Support All Main Aircraft Types – Rotary, Propeller and Jet Engined Aircraft.

Support All Main Aircraft Types – Rotary, Propeller and Jet Engined Aircraft.

Support All Main Aircraft Types – Rotary, Propeller and Jet Engined Aircraft.

Support All Main Aircraft Types – Rotary, Propeller and Jet Engined Aircraft.

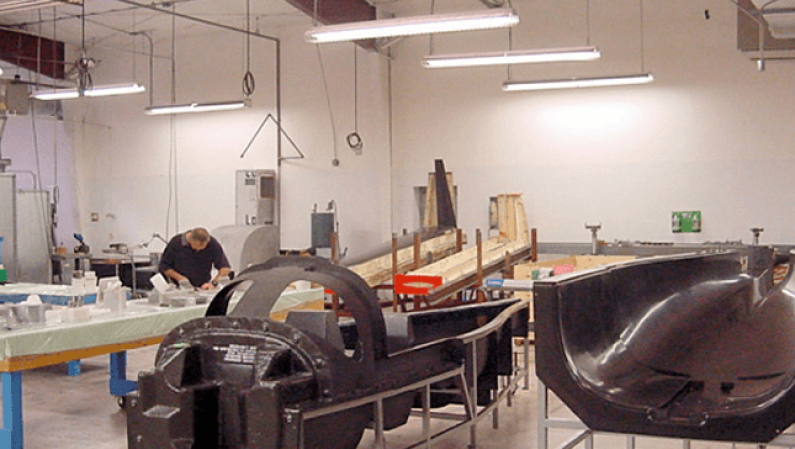

Since 1993, Matrix Composites has been at the forefront of innovative composite manufacturing, specializing in highly complex integrated resin structures for a variety of applications, including the aerospace industry. With a focus on precision and performance, our Liquid Resin Molding processes, including RTM, CVM, and HiRPM®, set us apart in the industry. We pride ourselves on our extensive expertise and commitment to delivering superior composite solutions to the global aerospace market.

While there are any number of components that are necessary to make an aircraft fly, it’s safe to say that the engine may be the most important.

In an aircraft or its engine, when a component’s job is to rotate, it is going to generate a measurable amount of noise and vibration as a result. Helicopter rotors are no exception.

Aircraft vibration can quickly build from an inconvenience for flight crew and passengers to an expensive problem for maintenance technicians.

Dynamic propeller balancing is a vital factor in maintaining an airplane’s service life. Strict guidelines determine tolerances for optimal performance and safe operation.

At Matrix Composites, we are dedicated to delivering outstanding results in every project we undertake. With a track record of success and a reputation for quality, we consistently exceed expectations in the design and manufacturing of high-performance composite products.

We adopt an impartial approach to materials selection and processing as we transition composite applications into consistent production. We approach every project with an unwavering commitment to excellence, leveraging our expertise and state-of-the-art manufacturing processes to develop innovative solutions for even the most challenging applications.

For unparalleled expertise, advanced technology, and superior quality in composite manufacturing, choose Matrix Composites. Learn more about how we can help bring your composite visions to life.